Jasper Hydroponic Garden

jaspergrow.co | 2017-present | commercial & personal

SKILLS

consumer electronics, design of manufacture (DFM) / design for assembly (DFA), fluidics, rapid prototyping, 3D printing, CFD simulation, FEA, rotomoulding, injection moulding, sheet metal forming, QA/QC, product management

OVERVIEW

A friend and I developed a consumer hydroponic garden based on the Nutrient Film Technique, an technology popular with commercial growers for leafy greens, herbs, and certain fruits like strawberries. I led our engineering, feature development, and horticulture research, prototyping the system & each new feature before completing our DFMA.

We sell both D2C and through retail partners.

Product shoot in 2023 with the V0 design. Photography by the wonderful Susana Silva

Customer feedback from our V0 design.

EARLY PROTOTYPING & CONCEPT WORK started with a rough COTS and FDM 3D printed prototype in my bedroom. Once some key parameters (flow rate, angle, length, and spacing) were resolved I moved into product design in CAD and using cardboard mockups. Our first functional “looks-like” prototype was made with a combo of rotomoulding and CNC milling.

ROTOMOLDING the tank was the first tooling commitment. Its a relatively large mould so we had to use a thicker mould to boost rigidity & avoid warping. Several rounds of surface refinement were needed before we were satisfied with the final result. The inlet and outlet are CNC milled.

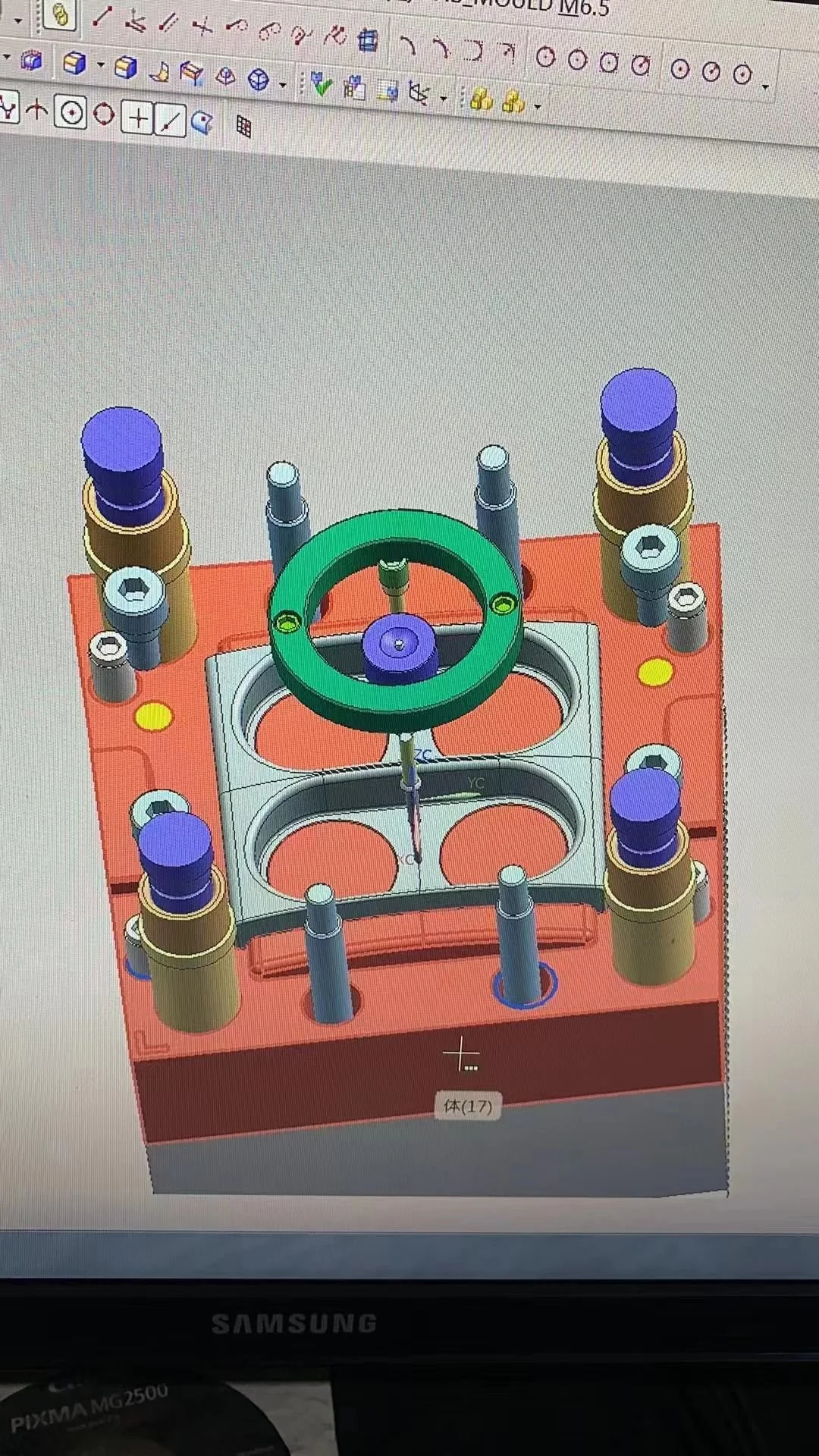

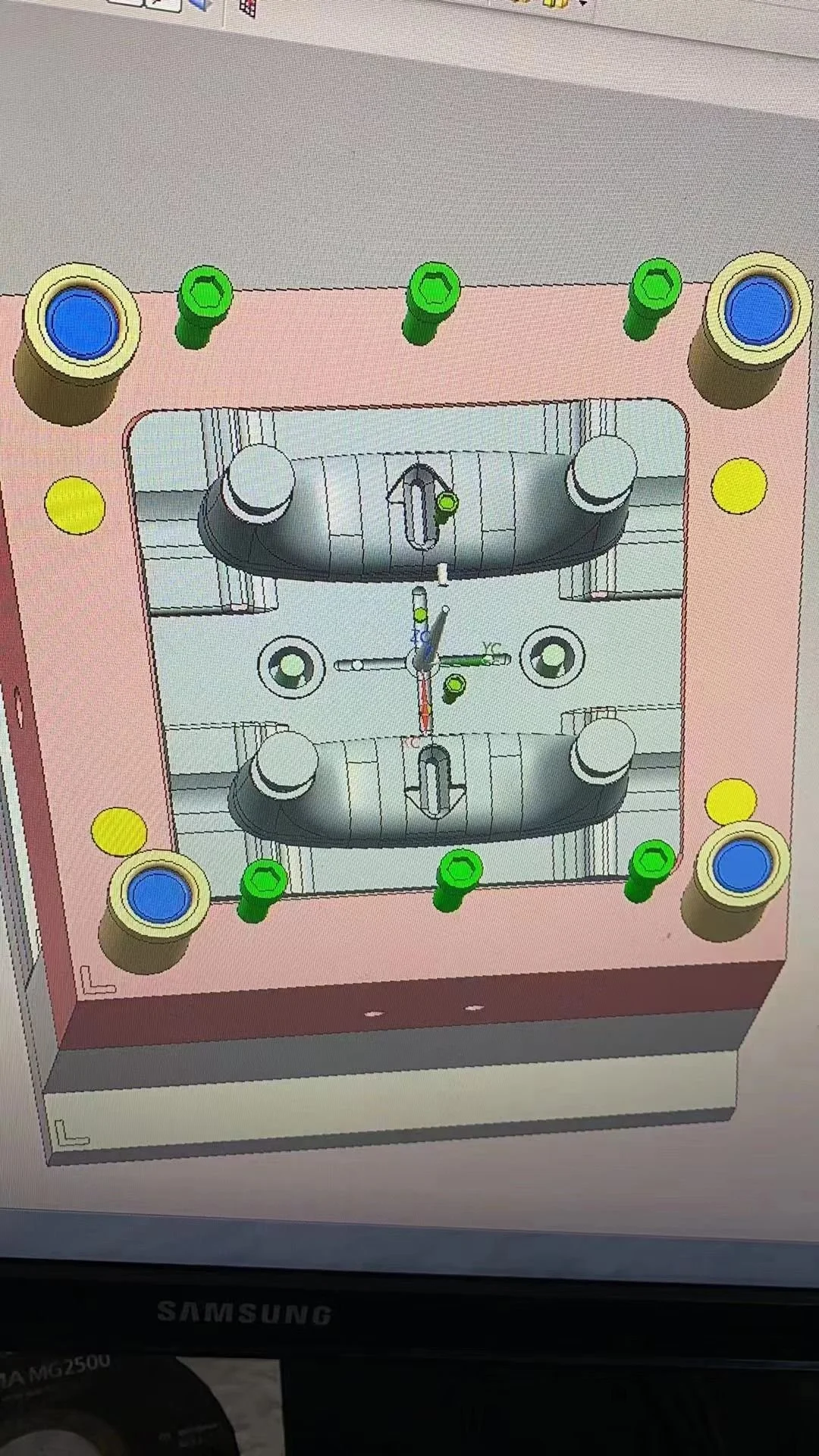

INJECTION MOLDING the lids, feet, & end caps came next. Their smaller size means shrinkage and warping are less of a concern. We worked with the factory to refine the molds, improving tolerances, surface finishes, and making minor feature additions.

IM tooling for lids

IM tooling for feet

IM tooling for end caps

Improvement to surface finish after refinement of the end cap tooling

Commercial-grade hydroponics tech for consumers

In 2017 I moved to Rothamsted Research to develop DryGro’s new crop in their controlled environment glass houses. I played with a few hydroponic techniques alongside our deep water test systems and the nutrient film technique (NFT) got me excited. Its the dominant technique used by commercial growers for a wide range of produce but there are no “nice” consumer versions.

NFT has some great advantages:

Optimal mix of water, aeration, and nutrient distribution

Simple and cheap hardware

Nice & clean workflows

Amazing results for leafy greens, strawberries, and herbs

Simple technique: expose the roots to a very shallow flow of fertilised water, allowing them to breath while absorbing nutrients and water. Ample O₂ promotes root health and improves the plants rate of nutrient uptake by up to XX%.

The majority of consumer hydroponics use “deep water culture” systems, aka a pot of fertiliser water that may or may not have aeration. This works well for industrial producers but aeration, nutrient management, and water quality management don’t scale down nicely.

Core operating principle: make it reliable and robust enough for novices to have a great growing experience.

Default to great growing conditions

One pump to operate

Simple “scoop” nutrient system. No automated nutrient dosing, pH management, or aeration

Completely leak-proof design. Nobody wants their living room flooded

Beautiful

Large enough capacity to buffer nutrients and to operate for weeks without maintenance or topping up