Portfolio

Jasper

Habit-building hydroponic garden consumer electronics

2022 - Present

I developed Jasper from concept to commercial production with two friends as a passion project. It ties together my love of plants, hardware prototyping, and building great products that empower others.

My role as Engineering Lead has focussed on modelling and rapidly prototyping new features, then translating them through DFMA to production alongside our factory partners.

DryGro

Enzyme extraction for F&B industry from plants in climate-insecure regions

2016 - 2024

I joined an Oxford spin-out to bring a new and promising crop, Lemna, to the world. We built two green-field facilities in rural Kenya, grew the team from 2 to 30, and worked with dozens of research partners and suppliers to develop the crop production and biorefining systems needed to realise our goal. I served as CTO and head of engineering.

PrototypeFluids

Accessible microfluidics for hobbyist and academic biotech researchers

2015 - 2016

My masters thesis - designed and built a custom PCB-mounted microfluidics product for automating microfluidic workflows. I worked with the London Centre for Nanotechnology, Imperial College’s Synthetic Biology Laboratory, and the London Biohackspace during product discovery, prototyping, and validation.

CARV

AI ski coach wearable (getcarv.com)

2015

Starting from a breadboard prototype, I took on the product design and hardware development alongside our embedded systems & electronics engineer. We spent 2 months at HAX accelerator in Shenzhen rapid prototyping and working with factories to bring the product to life.

The product had a successful Kickstarter, raising £275k via 1,200+ backers, with over 20,000 units sold since.

DIY Laser Cutter

Large-format homebuilt laser cutter

2013

To expand my prototyping skills and home workshop, I built a custom CO2 laser cutter in my garage.

Dimensions: 1x1m

Laser: 40W CO2, liquid cooled

Motors: NEMA23

Controller: GRBLshield + Arduino Uno + Universal G-code Sender

Compiler: Inkscape + Gcodetools extension

Single Point Incremental Forming

Thesis paper on a CNC rapid sheet metal forming technique

2012

During my final year of undergraduate studies I completed a research project into CNC incremental forming of sheet metal. I designed & turned new tool shapes and characterised their forming limits and effect on surface finish.

You can read my paper here: Examining Tool Shape in Single Point Incremental Forming

DFMA Teardown

A 1-day rapid teardown and reassembly of an SK410

2016 - 2024

During the first week of my masters me and 3 classmates got our hands dirty in the shop disassembling, analysing, and then building a physical exploded view of Shark Pro Steam & Spray SK410 Series floor cleaner.

This model now lives in Europro’s European office.

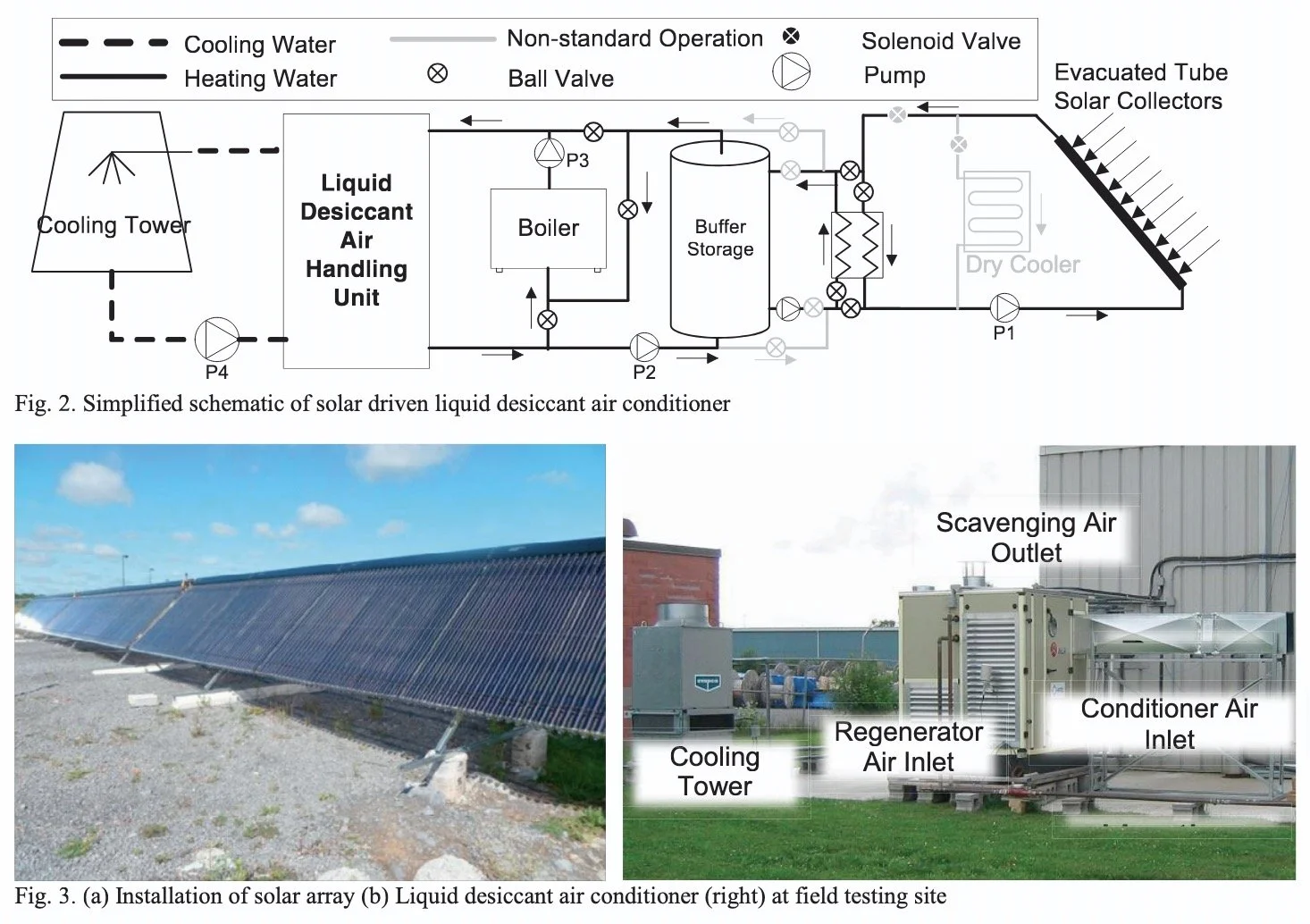

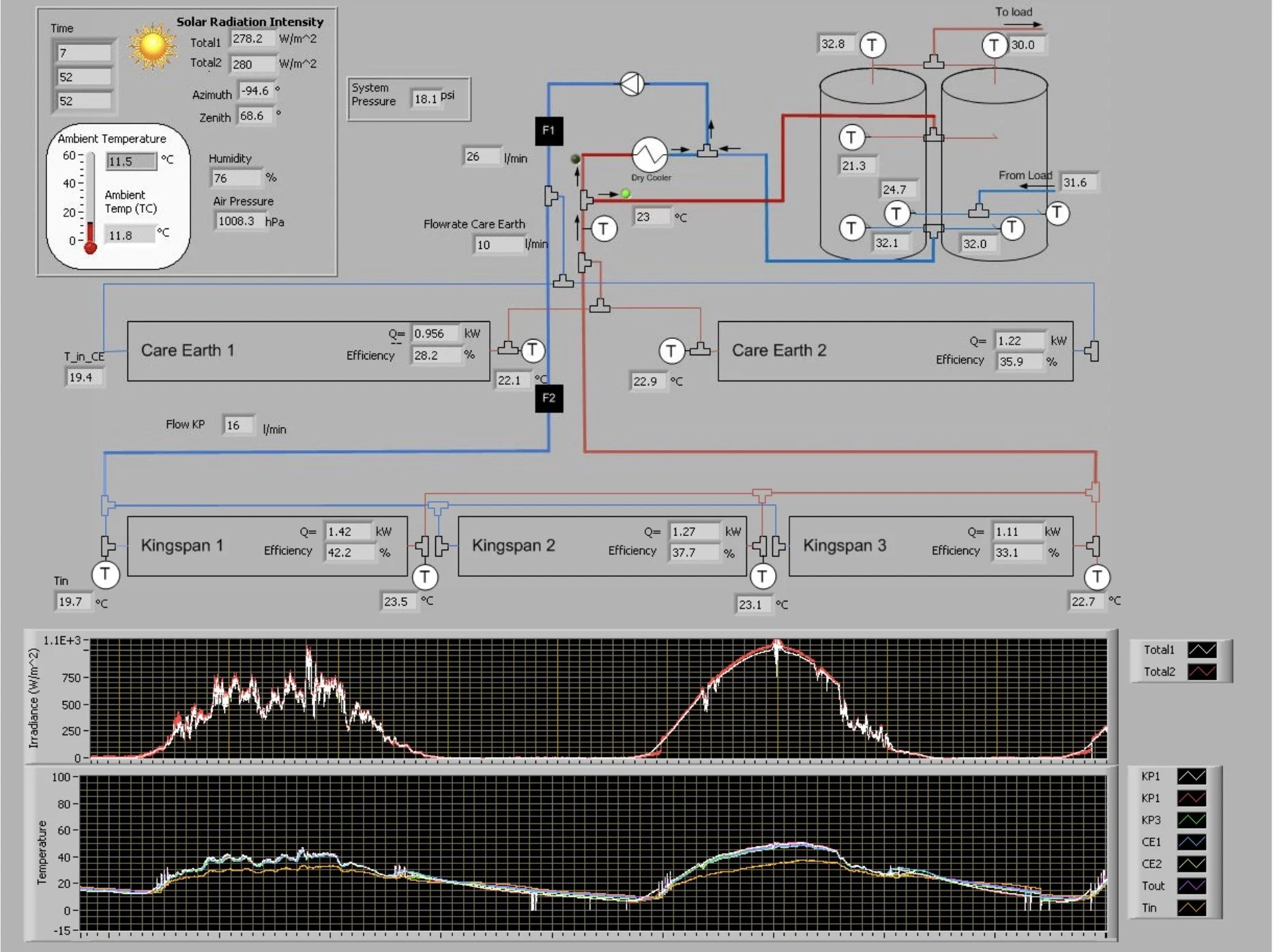

Liquid Desiccant Solar Air Conditioning System

Research job building and commissioning an experimental LDAC system

2011

One summer spent in the sun building and commissioning a novel AC system in the Queen’s Solar Calorimetry Lab. It was a deep dive into psychrometrics and building & troubleshooting fluid systems.

You can read an overview paper on the system and its performance here: Performance Evaluation of a Liquid Desiccant Solar Air Conditioning System

DIY Keyboard

Soldered and programmed a series of split column-staggered keyboards

2021 - 2022

Modern keyboards are still modelled after the typewriter. I tested and built several newer designs to improve the ergonomics and efficiency of my time at the computer.

Here’s a little guide I made on Notion:

Cawley’s Mechanical Keyboard Guide